Enhancements Make Pro-Treat Even Better

Enhancements Make Pro-Treat Even Better

Dolphin Bay has updated Pro-Treat, our digital treatment platform which provides users with clear advantages such as streamlined operations and simplified management for their timber treatment plants.

Plant managers and operators benefit from new features that make it easier to uphold high operational standards, saving time and enhancing productivity.

“We’ve added more functionality to make Pro-Treat even more user-friendly than it already was,” added Wayne Driemeyer, Dolphin Bay’s Pro-Treat Service Manager.

While some of the changes are small tweaks, others are significant, including important enhancements to reporting and stock management. “Pro-Treat users can now receive scheduled daily reports, which provide a full breakdown of what happened at the plant on that particular day,” Wayne explained.

“You can choose when you want to receive the reports, and who in your organisation you’d like to send them to. The information is all at your fingertips.“

“This includes treatment volumes, stock levels, retention levels, and so on. You can choose when you want to receive those reports, and who in your organisation you’d like to send them to. The information is all at your fingertips. You don’t have to go looking for it.”

These reports give treatment plant managers unprecedented insights, even when they are off-site. “This is very helpful, as plant managers are often travelling, or at plantations, or in production meetings,” Bertus added.

Pro-Treat is now also more proactive on stock management, sending alerts to plant managers when stock needs to be reordered. “We sometimes find that operators don’t realise when the plant needs more product, and new stock needs to be arranged in a rush,” said Bertus. “Pro-Treat can now set a reorder level, and when that is reached, it sends an alert to the plant manager.”

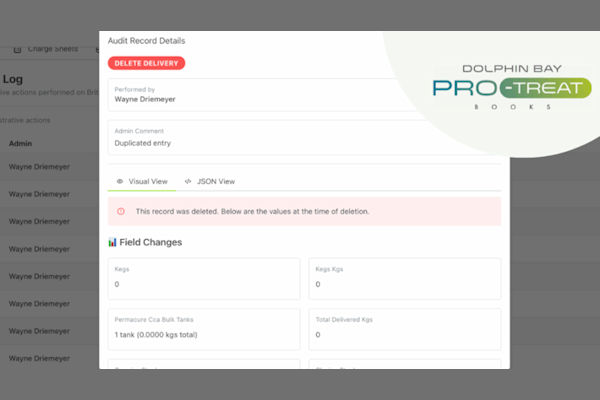

In one of the most significant updates, Pro-Treat now allows data to be edited and input errors to be corrected. “If a plant operator makes a mistake in their data, the plant can contact Dolphin Bay, and we can fix any errors made at any time in the past,” said Bertus. “What sets this apart is that at no point do we compromise the auditability of the system, as a changed tracking log is accessible to the management and auditors.”

Said Wayne: “Most of the support calls we get on Pro-Treat relate to plant operators inputting the incorrect data and then realising that they’ve made a mistake.

“We have seen such a dramatic improvement that some plants using Pro-Treat increase their production by a conservative 30%.”

“This update is a direct response to that – and by creating a full audit trail, it maintains the integrity of the system and provides accurate record-keeping. If plant operators do make an error while using Pro-Treat, it tends to stick out; you’ll see it almost immediately because the stock won’t balance.”

Having said that, we have observed that the longer a plant uses Pro-Treat, the fewer mistakes are made, said Wayne.

Plants using Pro-Treat also make huge improvements in their efficiencies. “We have seen such a dramatic improvement that some plants using Pro-Treat increase their production by a conservative 30%. While this will not be true for all plants, it clearly indicates the effectiveness of this management tool.

“I work very closely with Pro-Treat, and with the treatment plant operators and plant managers who use it. It’s clear that it’s making a big difference in our industry,” concluded Wayne.

Source: Dolphin Bay